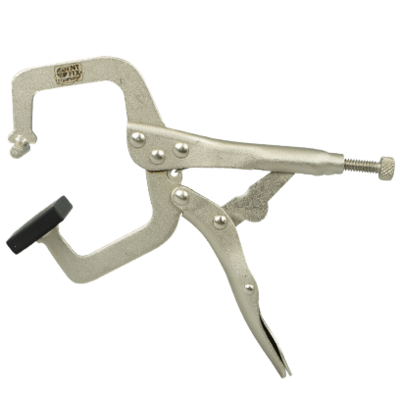

Shunting Pliers

I-CAR Shunting Procedure PDF | I-CAR Online Article

Squeeze-type resistance spot welding (STRSW) sometimes requires additional measures, in the form of shunting the current flow, to create a successful spot weld. Conductive coatings on steel, such as zinc or weld-through primer increase the resistance but a successful weld can be accomplished. Non-conductive coatings on steal, such as E-Coat (a corrosion-resistant primer applied to parts by the manufacturer) inhibit the completion of the spot weld. The E-Coat on the mating surfaces can be saved when using STRSW with the use of the Dent Fix Shunting Pliers (DF-SP360).

Simply remove the coating from only the outside surfaces, position the shunting clamp at the spot weld site, and the spot weld is made at the adjacent site. The current chooses the path of least resistance when confronting the non-conductive E-Coat, the shunting pliers facilitates the electrical current from one side to the other. The E-coat at the mating surface burns away.

The process is very quick and despite the fact most of the current flows between the electrode tips the current detour was brief but necessary.

- iCAR requires with the STRSW process, shunting of the current is required for the first weld when there is a nonconductive coating like E-coat or adhesive on the mating flanges.

- iCAR requires when weld bonding, a dedicated shunting clamp should be used for the best weld performance.

- Help saves the E-coat since less is removed using a shunting pliers.

Max amperage: 145 amps

Copper Wire: 4 Gauge

90 day warranty.

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov